Cooling tower working principle and installation method

Key words:

Classify:

Case Study

Hotline:

Cooling tower working principle and installation method

Cooling Tower Working Principle and Installation Method

Cooling towers play a significant role and are essential equipment in many large factories, shopping malls, and thermal power plants. They cool hot water by exchanging heat with air inside the tower, transferring waste heat to the air and dissipating it into the atmosphere.

This article will take you through a deep dive into the principles and types of cooling towers.

I. Basic Principles of Cooling Towers

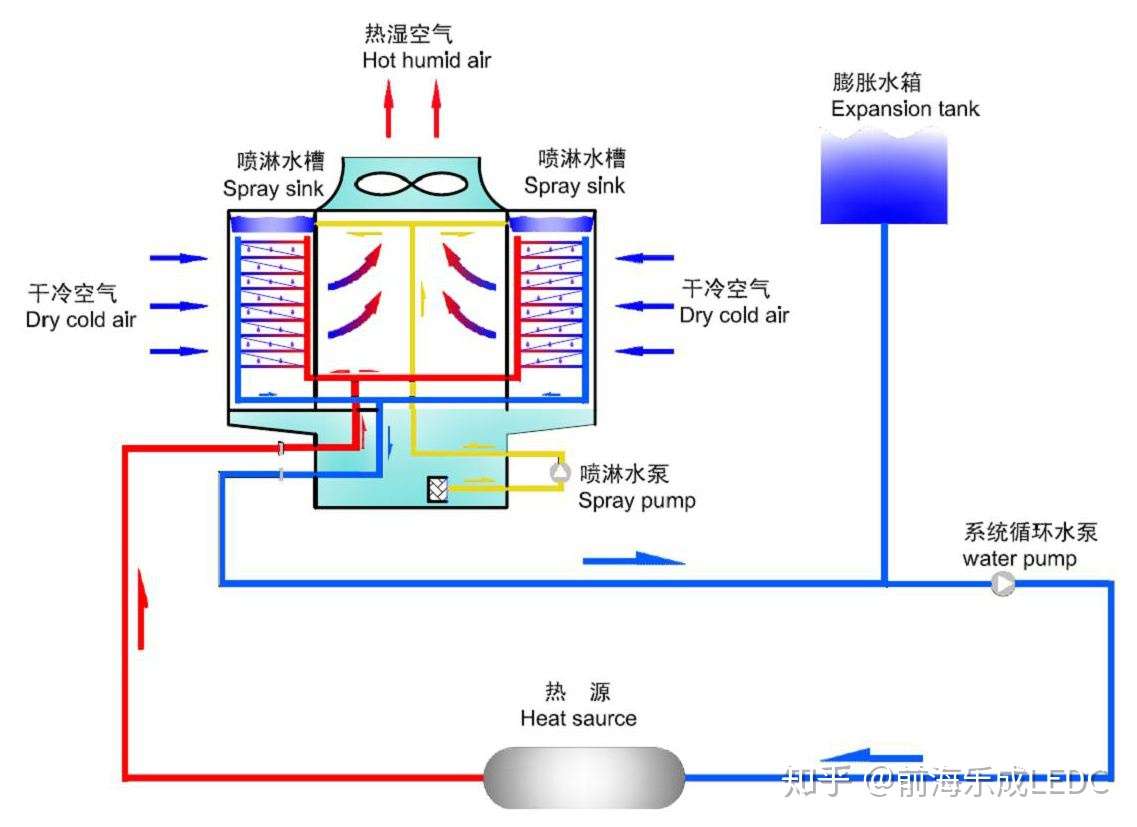

A cooling tower is a device that cools water by bringing it into contact with air (directly or indirectly). It uses water as a circulating coolant, absorbing heat from a system and releasing it into the atmosphere, thereby lowering the internal temperature and creating a recyclable cooling water system.

1. Heat Dissipation Relationship in Cooling Towers

In wet cooling towers, the temperature of the hot water is high, and the temperature of the air flowing over the water surface is low. The water transfers heat to the air, which carries it away and dissipates it into the atmosphere. Water dissipates heat to air in three ways:

① Contact heat dissipation;

② Evaporation heat dissipation;

③ Radiation heat dissipation.

Cooling towers mainly rely on the first two methods of heat dissipation; radiation heat dissipation is minimal and can be neglected.

2. Principle of Evaporation Heat Dissipation

Evaporation heat dissipation is achieved through mass transfer, i.e., through the continuous diffusion of water molecules into the air.

Water molecules have different energies; the average energy is determined by the water temperature. Near the water surface, some water molecules with high kinetic energy overcome the attraction of nearby water molecules and escape the surface to become water vapor. Because high-energy molecules escape, the energy of the water near the surface decreases.

Therefore, the water temperature decreases; this is evaporative heat dissipation.

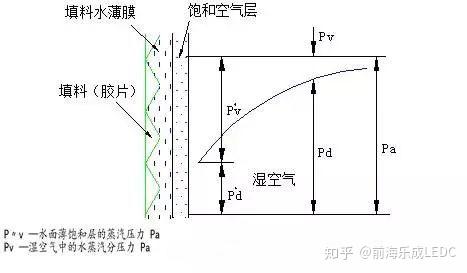

It is generally believed that the evaporating water molecules first form a thin layer of saturated air on the water surface, with the same temperature as the water surface. Then, the rate at which water vapor diffuses from the saturated layer into the atmosphere depends on the difference between the water vapor pressure of the saturated layer and the atmospheric water vapor pressure, i.e., Dalton's Law. This process can be represented by the following diagram.

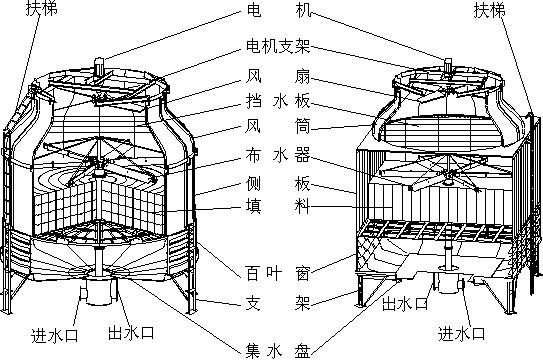

II. Basic Structure of Cooling Towers

Air conditioning cooling towers mainly consist of the tower body, motor, fan, fill, water distribution device, and water pipes.

Support and tower body: External support

Fill: Provides the largest possible heat exchange area for water and air

Cooling basin: Located at the bottom of the cooling tower, receives cooling water

Drift eliminator: Reclaims water droplets carried away by the airflow

Air inlet: Air intake of the cooling tower

Water distribution system: Sprays cooling water

Fan: Delivers air into the cooling tower

Axial fan: Used for induced draft cooling towers

Axial/centrifugal fan: Used for forced draft cooling towers

Cooling tower louvers: Average intake airflow; retain moisture inside the tower

III. Types of Cooling Towers

With the rapid development of industry, there are many different types of cooling towers. They are basically divided into the following categories:

1. By ventilation method:① Natural draft cooling towers; ② Mechanical draft cooling towers; ③ Hybrid draft cooling towers

2. By water and air contact method:① Wet cooling towers; ② Dry cooling towers; ③ Dry/wet cooling towers.

3. By the flow direction of hot water and air:① Counterflow cooling towers; ② Crossflow (direct exchange) cooling towers; ③ Mixed flow cooling towers

4. By application field:① Industrial cooling towers; ② Air conditioning cooling towers.

5. By noise level:① Ordinary cooling towers; ② Low-noise cooling towers; ③ Ultra-low noise cooling towers; ④ Ultra-quiet cooling towers.

6. By shape:① Round cooling towers; ② Square cooling towers.

7. By whether water and air are in direct contact:① Open cooling towers; ② Closed cooling towers (also known as closed cooling towers, sealed cooling towers).

There are other types of cooling towers, such as jet cooling towers and fanless cooling towers.

The above is basic knowledge about cooling towers. In the next section, we will focus on the design and selection of cooling towers. Interested friends can come and learn together.

Related Products

Product Message

Website

Address: 2km south of the toll station in Anqiu City, Shandong Province (FRP Industrial Park)

Tel:+86-13685366350

E-mail:13685366350@163.com

Powered by www.300.cn | Privacy Policy